Description

Your compressed air system is almost certainly leaking money. Industry data shows the average factory has 20-30 undetected leaks costing £10,000-25,000 per year in wasted electricity. You can't hear them — they're ultrasonic — but our acoustic imaging camera can see them.

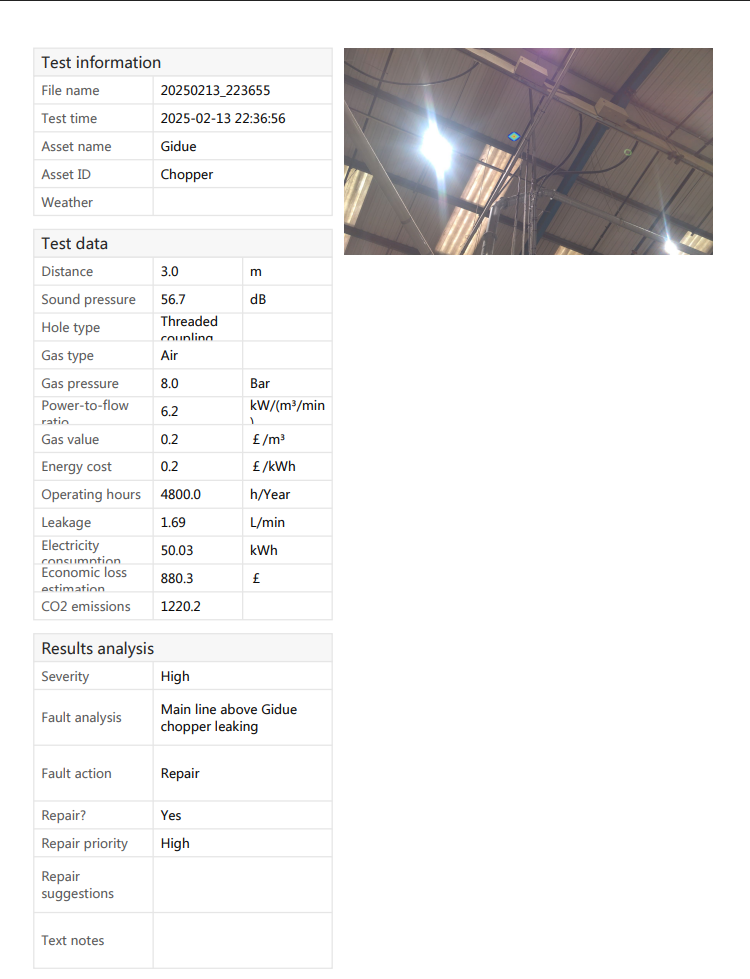

We scan your entire compressed air and vacuum system with a 200-microphone acoustic camera that detects ultrasonic leak signatures and displays them as a visual hotspot on screen. Every leak is tagged, photographed, measured, and costed.

What you get:

Full facility scan — every pipe run, fitting, valve, tool connection and machine checked while your plant runs normally, no downtime required.

Detailed PDF report within 48 hours containing: total number of leaks found, total annual waste in £ and kWh, CO2 emissions figure, individual leak inventory with location photo, sound level, flow rate and annual cost for each leak, and a prioritised repair plan showing which leaks to fix first for maximum savings.

Follow-up consultation call to walk through the findings and answer questions.

What it typically costs to ignore leaks: £10,000-25,000 per year for a mid-size facility. What it costs to find them: £1,250. Most customers see payback within 2-3 months from repairs alone.

Smaller facility or simple system? Contact us for a custom quote — half-day surveys available from £750.

Coverage: Up to 8 hours on-site. Travel included within 50 miles of Peterborough. 29 years of industrial maintenance experience behind every survey.